page

page

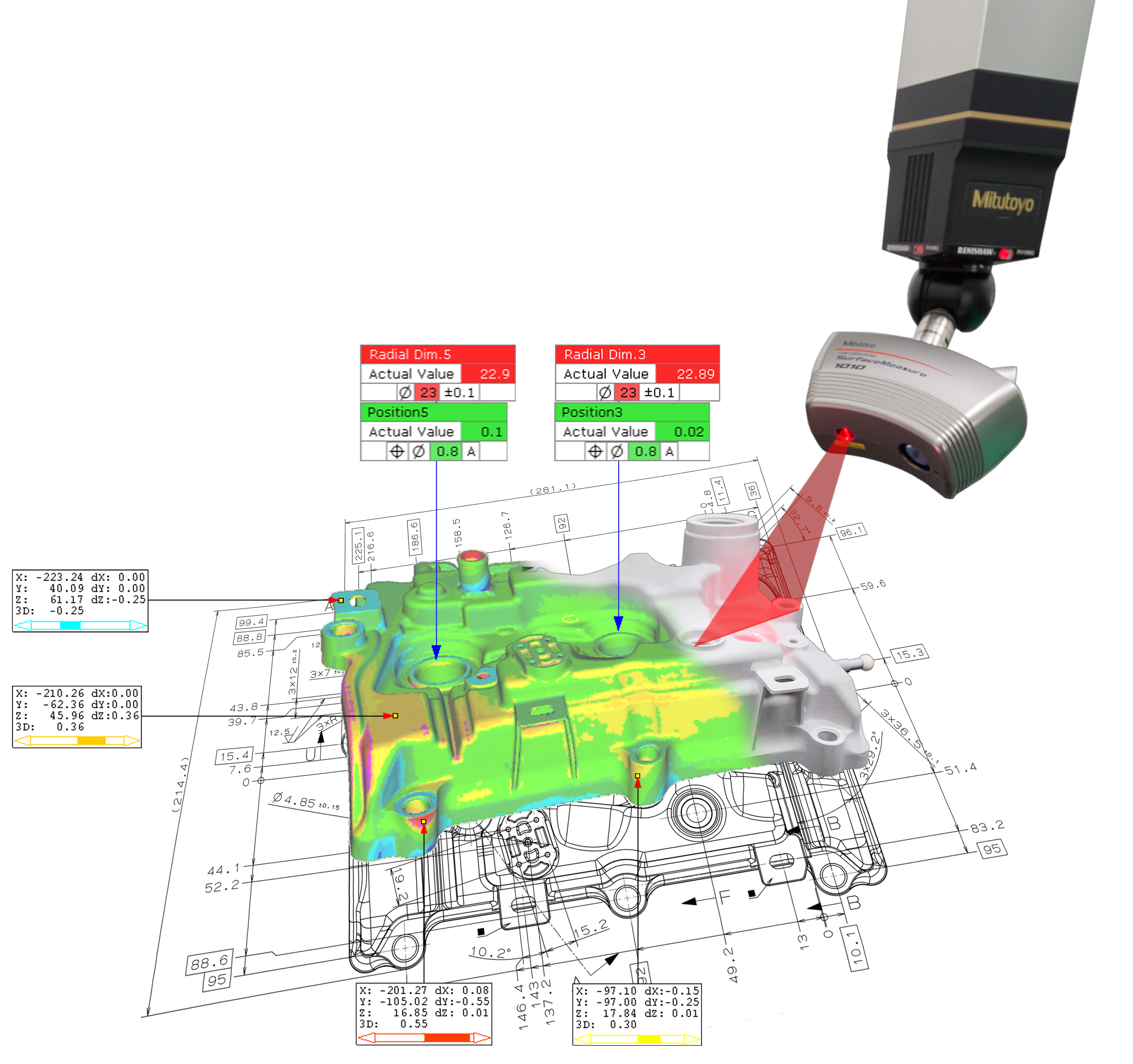

3D/2D Inspection

3D Inspection

(3D Model Comparison)

3D inspection is a process of inspecting a physical part using advanced technologies, it involves the use of specialized equipment as 3D scanners and optical inspection systems to capture precise measurements and data points of the object's surface. And then comparing the data against the original CAD models. Any deviations or defects can then be identified and analyzed, and corrective action can be taken if necessary.

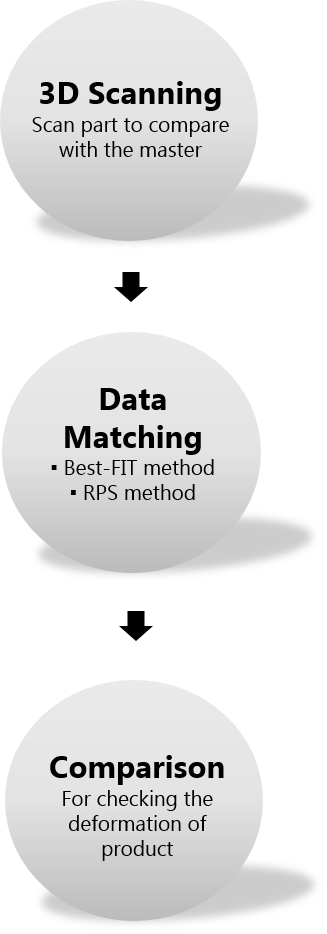

Here are the general steps involved in the 3D inspection process:

1. Preparation: Cleaning the object, removing any debris, or applying coatings or markers to help with scanning or measurement.

2. Scanning: The object is scanned using a 3D scanner captures the surface geometry of the object as a point cloud or a 3D mesh.

3. Data processing: The point cloud or 3D mesh data is processed using specialized software to remove any noise, smooth the surfaces, and align the data to a common coordinate system.

4. Comparison to CAD model: The scanned data is compared to the CAD model to identify any deviations or differences. This helps to determine whether the physical object meets the design specifications.

5. Inspection analysis: The scanned data is analyzed to measure and verify the dimensions, tolerances, and features of the object.

6. Reporting: The results of the inspection analysis are compiled into a report that includes a summary of the inspection findings, any deviations from the CAD model or inspection criteria, and recommendations for corrective action if necessary.

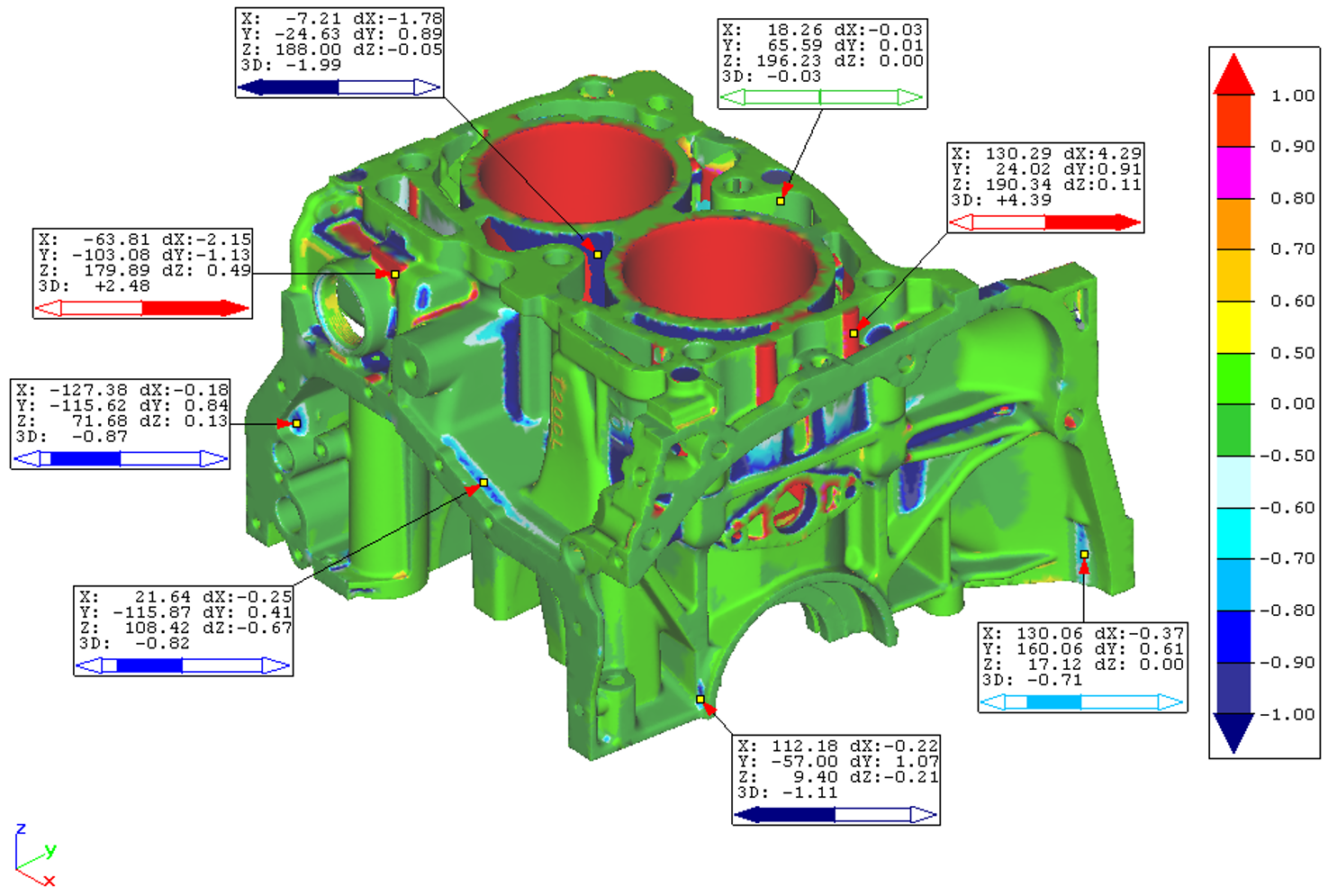

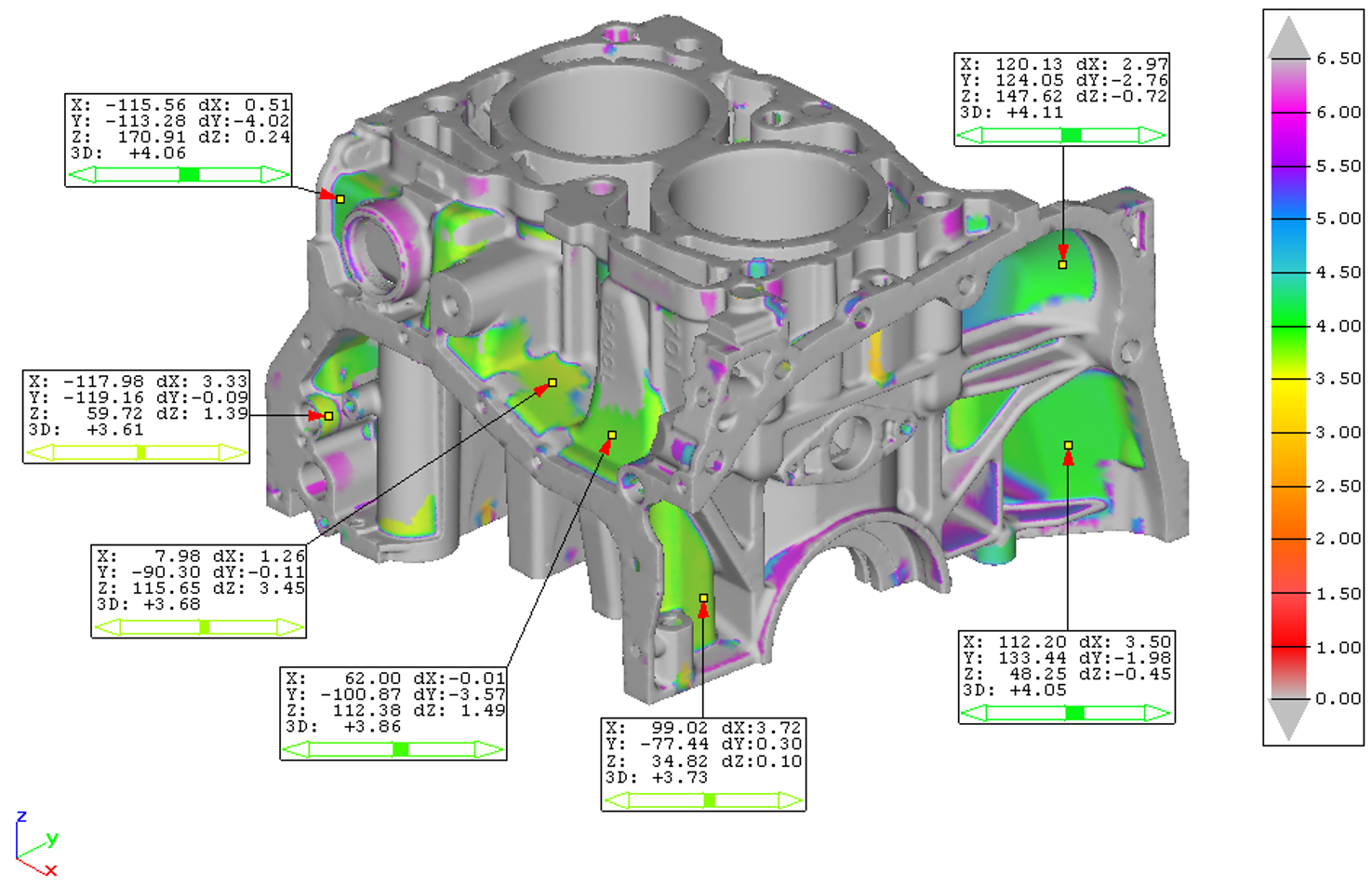

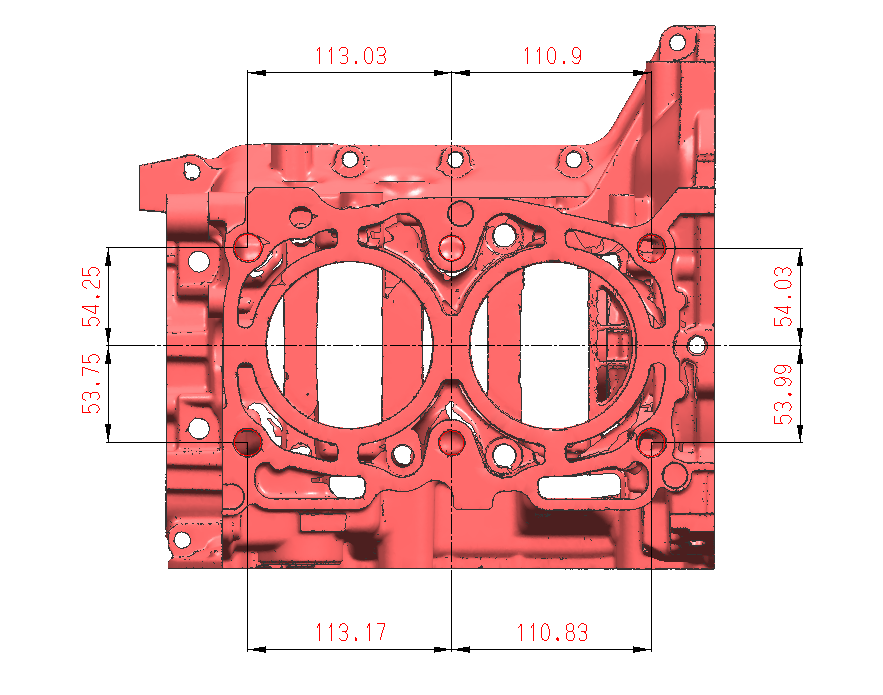

Deviation

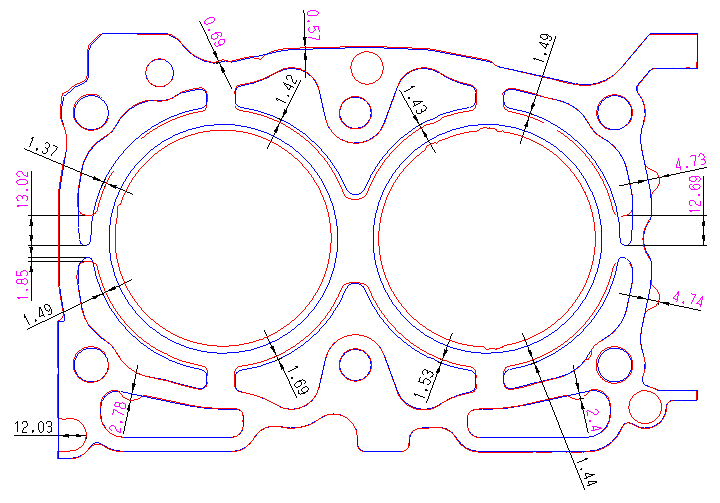

Thickness

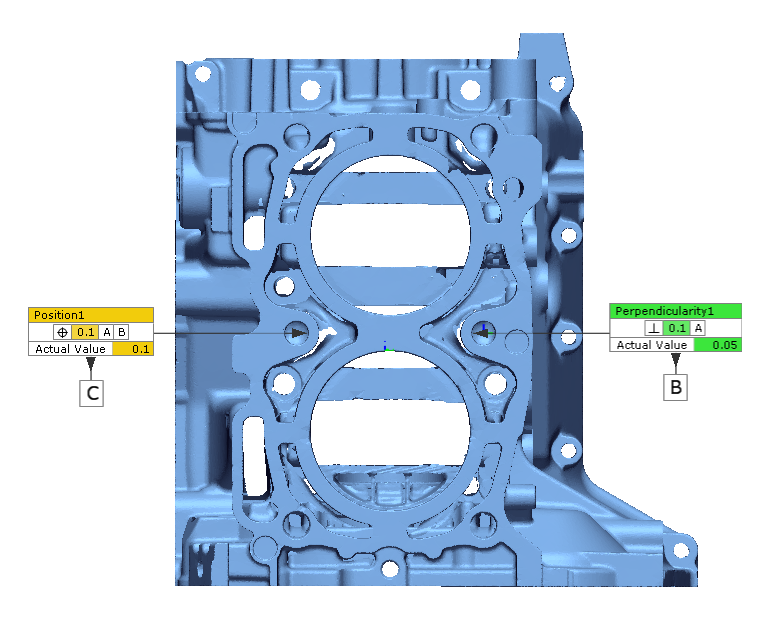

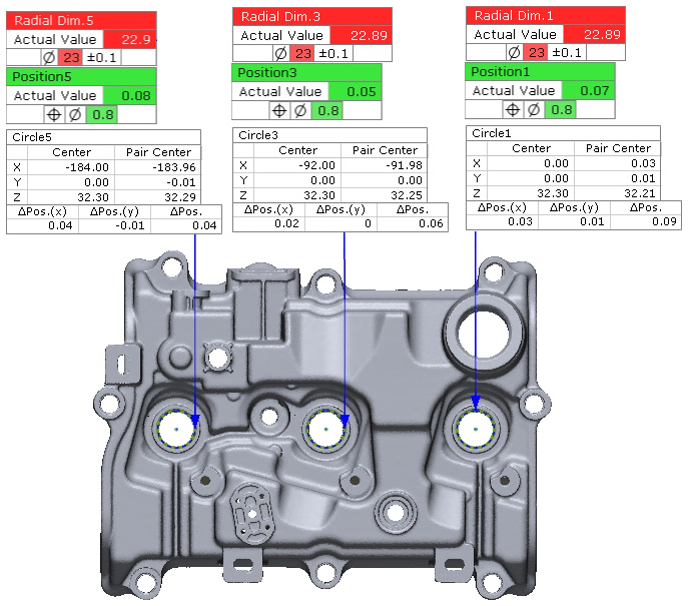

Dimension Check

Cross Section

Inspection Results

Results display is easy to understand which is convenient to all related people

Deviation: The difference between the actual physical object and its corresponding 3D CAD model. This difference can arise due to a variety of factors, including manufacturing variations, assembly issues, and other factors that may affect the final shape or dimensions of the object.

Thickness: Checking a scanned data which unnecessary to cut an actual part

2D Dimension: Dimension measurement directly from the scanned data

Cross Section: To check dimeter, dimension, etc. from the scanned data compared with CAD

GD&T inspection results typically use a set of symbols, such as position, flatness, perpendicularity, etc., to indicate the type of measurement being taken and the tolerance allowed. The inspection results are then compared to the GD&T design specifications to determine if the part or feature is within the allowed tolerance limits or if it needs to be rejected or reworked.

Benefit and Advantage

- Increased accuracy: 3D inspection can provide much higher accuracy than traditional inspection methods. By using 3D scanning and measurement technologies, even complex geometries and surface features can be inspected with high precision.

- Time and cost savings: Compared to traditional inspection methods, 3D inspection can save time and reduce costs. The use of automated inspection software and equipment can speed up the inspection process, reduce errors, and minimize the need for rework.

- Improved quality control: 3D inspection enables manufacturers to perform comprehensive quality control checks and ensure that products meet design specifications. This can help to identify and correct defects or issues before they become bigger problems.

- Increased productivity: By automating the inspection process, 3D inspection can free up workers to focus on other tasks, improving overall productivity.

- Enhanced design: 3D inspection can be used to evaluate the performance and quality of products, which can help to identify areas for improvement and refine the design of future products.

Applications

Sample of 3D Inspection Cases

- Aerospace industry: inspection of aircraft components such as turbine blades, wings, and engine parts to detect defects or deviations from design specifications.

- Automotive industry: inspection of car body parts, engine components, and other automotive parts to ensure that they meet quality standards and are within tolerance limits.

- Medical industry: inspection of medical implants, prosthetics, and devices to ensure that they meet design specifications and are safe for use in patients.

- Electronics industry: inspection of circuit boards, chips, and other electronic components to detect defects and ensure they meet specifications.

- Packaging industry: inspection of packaging materials, such as bottles, cans, and boxes, to ensure they meet quality and safety standards.

- Art and archaeology: inspection and restoration of artifacts, sculptures, and ancient structures to preserve cultural heritage.

Mold maintenance: 3D inspection is an important tool for mold maintenance in manufacturing. By providing detailed analysis of the mold's geometry and identifying any deviations from the original design, 3D inspection helps to ensure that molds are functioning properly and producing high-quality parts. This can help to reduce downtime, improve efficiency, and minimize defects in the final product.

15 February 2024

Viewed 14778 times