page

page

Measurement

We accumulated know-how as a pioneer in this field from the dawn of non-contact laser measurement technology. We are taking a system to provide the best measurement and evaluation in a short time from measurements of more than 4,500 items ranging from raw materials, molds, soft materials, art objects and so on. Measurement of hollow structure can be supported by collaboration with CT scan method. High-precision non-contact measurement (CMM) for visible part · Digital measurement with CT scan method for hollow structure part. We are establishing the technology to "digitize the whole thing" by matching the best of the advantages of both measurement technologies.

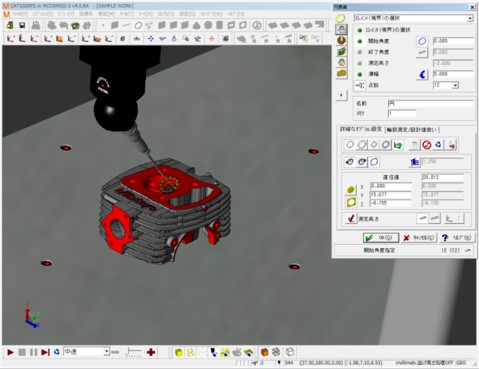

Inspection system · 3D model data check

3D model and 2D drawing comparison

Confirm and investigate defects on data, manufacturability

problems, etc.

Create automatic measurement program from 3D model and

prepare in advance

Prepare measurement program offline and shorten inspection

waiting time

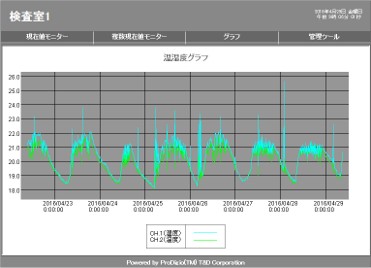

24 hour thermal management system

Creation of in-house measurement standards in three

dimensional measurement

Low difference in measurement method or measurement

result by the measurer

Reduce measurement uncertainty by decreasing

Quality Assurance System

At our company, we are monitoring the temperature and humidity in real time, not only in the dedicated measuring room, but also in the processing factory, from the commitment of "guaranteeing the product itself" beyond the frame of inspection.

In addition, we developed our own automated processing system for measurement data, the data acquired by measurement was transferred to the in-house data center on-time through the in-house LAN, and the evaluation on the tolerance was automatically judged and at the same time the measured value and the evaluation were described Report is created automatically.

We check thickness, fillet, gradient and compare 3D and 2D diagram against 3D model provided by customer.

We have prepared a system for feedback to customers after checking the problems on data and manufacturability problems.

Regarding measurement of processed goods, we prepare an automatic program in advance, judge pass / fail immediately after processing, reduce the state of waiting for inspection, and realize production start up in a short period of time.

In addition, the room temperature in the measuring room is constantly monitored for 24 hours, internal measurement standards are created to eliminate the difference due to the difference in the measurement persons, and the uncertainty included in the measurement result is reduced.

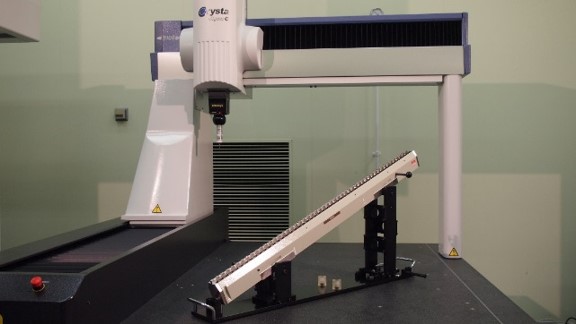

- Accuracy check inside the company by check master (including spatial accuracy by inclined platform)

- Maintaining optimal condition of CMM

- Strict accuracy control by confirming accuracy

We currently own 4 CMM units, contact type, non-contact 5 axis control and we develop the collaboration of our equipment for high accuracy of product measurement.

24 September 2018

Viewed 9597 times