page

page

Reverse Engineering Service

Reverse Engineering Service

Reverse engineering is the process of analyzing a product or system in order to understand how it works, often with the goal of reproducing or improving upon it. It involves taking apart and examining the components, subsystems, or code that make up a product or system in order to understand its functionality, design, and implementation. Reverse engineering is commonly used in fields such as software engineering, mechanical engineering, electrical engineering, and aerospace engineering.

Advantage of Reverse Engineering

- Product improvement: Customers may be interested in reverse engineering services to improve the design and functionality of existing products. By analyzing and understanding the existing product, reverse engineering can help identify areas for improvement and suggest new features or components.

- Cost savings: Reverse engineering services can also be attractive to customers who are looking to save costs on production. By analyzing and reproducing existing products, reverse engineering can help identify areas where cost savings can be achieved without compromising quality or functionality.

- Obsolescence: Customers may also seek reverse engineering services when the original manufacturer is no longer producing a product, or when replacement parts are difficult to obtain. By reverse engineering the product, a customer can ensure that they have access to replacement parts or components, even if the original manufacturer is no longer producing them.

- Intellectual property protection: Reverse engineering services can also be used to protect intellectual property rights. By reverse engineering a competitor's product, a company can identify potential patent infringements and take appropriate legal action.

- Competitive advantage: Reverse engineering can also provide a competitive advantage by allowing a company to quickly develop and launch new products based on existing products. By understanding the design and functionality of a competitor's product, a company can develop similar or improved products and gain a competitive edge in the market.

Reverse Engineering Process

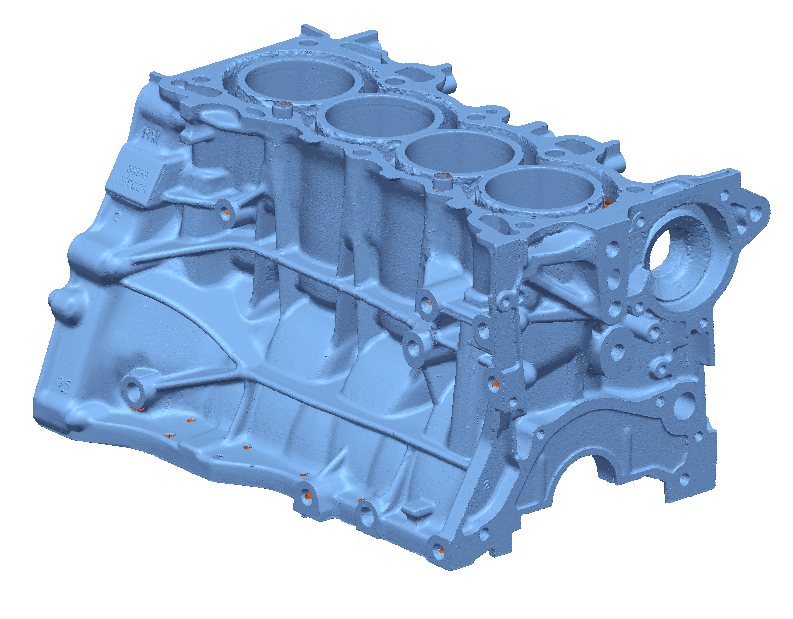

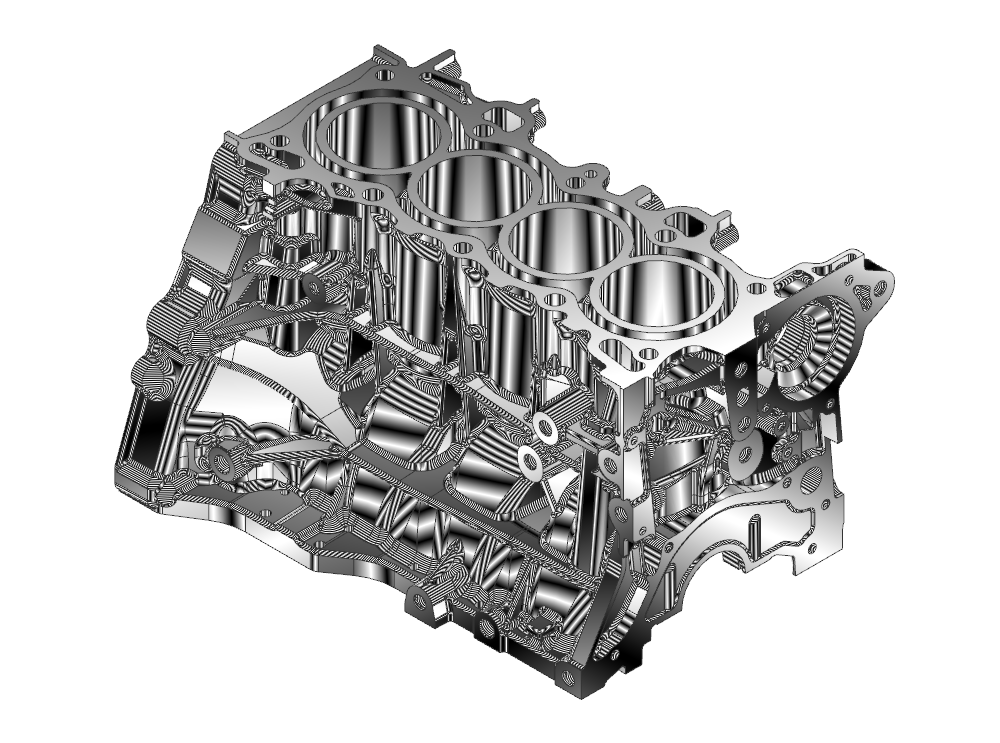

1. 3D scanning: The first step is to capture the physical shape and geometry of the object using a 3D scanner. The scanner captures the 3D data points from the object, which are then used to create a point cloud.

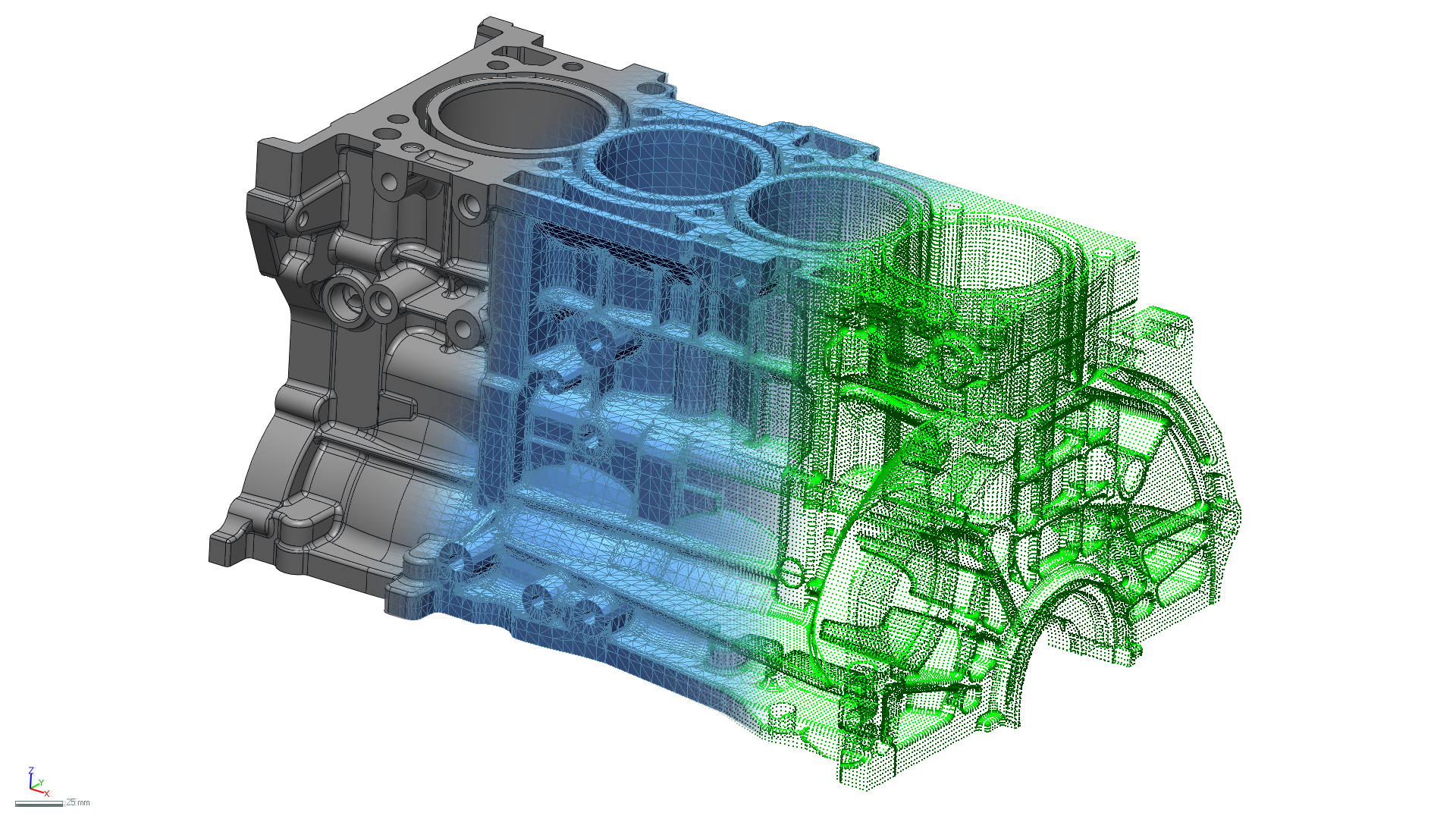

2. Point cloud processing & Polygon generation: Cleaned up point cloud data, and any noise or unwanted data is removed to create a clean and accurate point cloud. Once the point cloud data is processed, it can be used to generate a mesh which is a 3D model composed of a network of triangles that define the surface of the object which is the polygon.

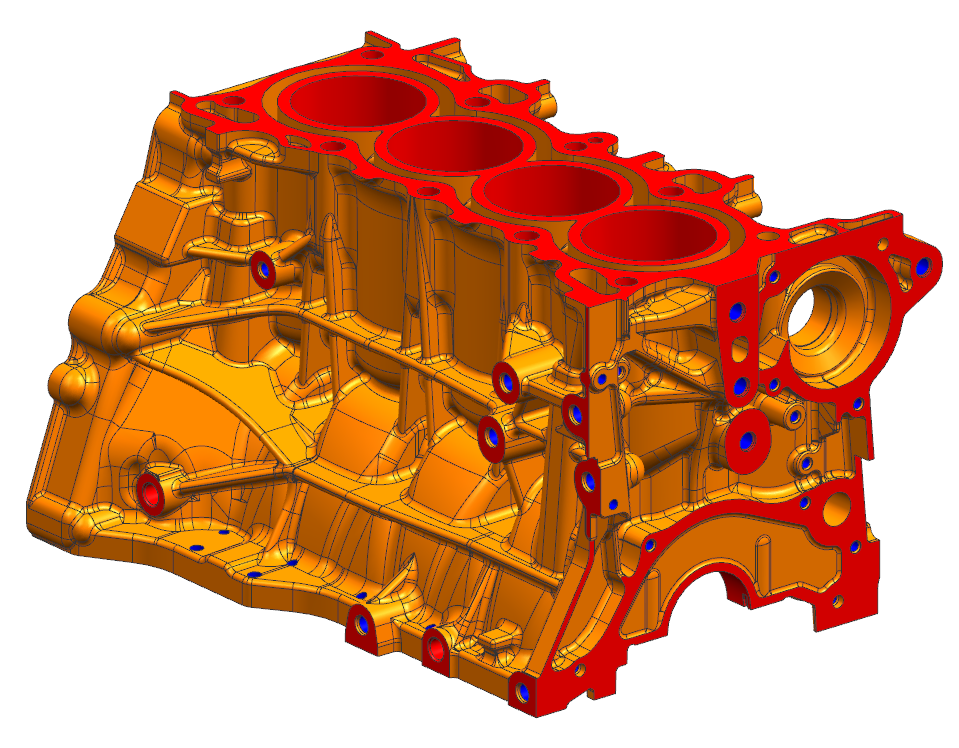

3. Modeling: The polygon can be imported into a reverse engineering software. In the reverse engineering software, it can be converted into a solid model using various tools, such as surface fitting or lofting. The solid model can then be refined and modified to match the original physical object.

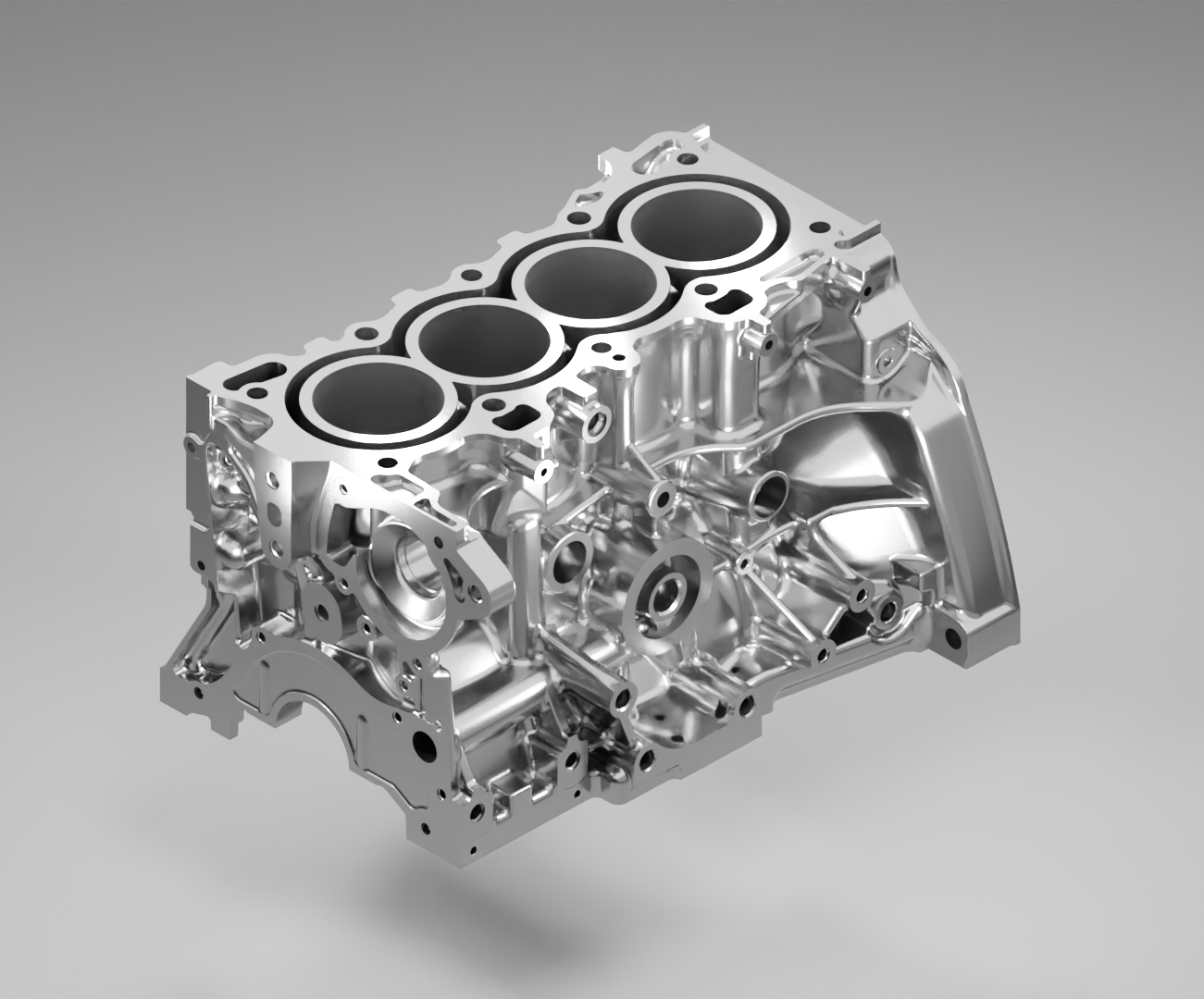

4. Finalizing the 3D model: Once the solid model is created, it can be further refined and modified to meet the design requirements. An important thing is the reversed model quality verification. The final 3D model can then be used for various purposes, such as 3D printing, CNC machining, or injection molding.

Data Quality Control

We prioritize the quality of data, therefore, we conduct quality checks to ensure that

our customers will received the quality data and can be used efficiently.

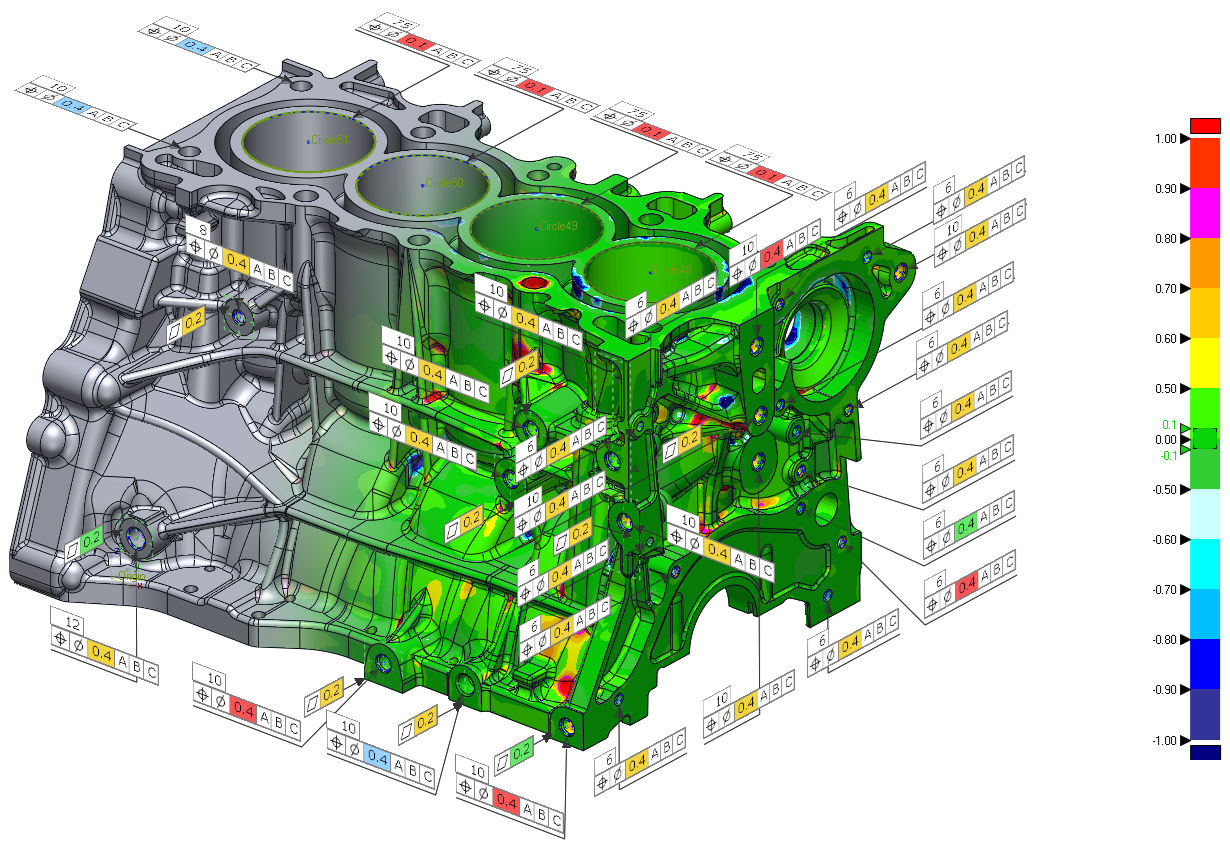

Thickness Checking

Draft Checking

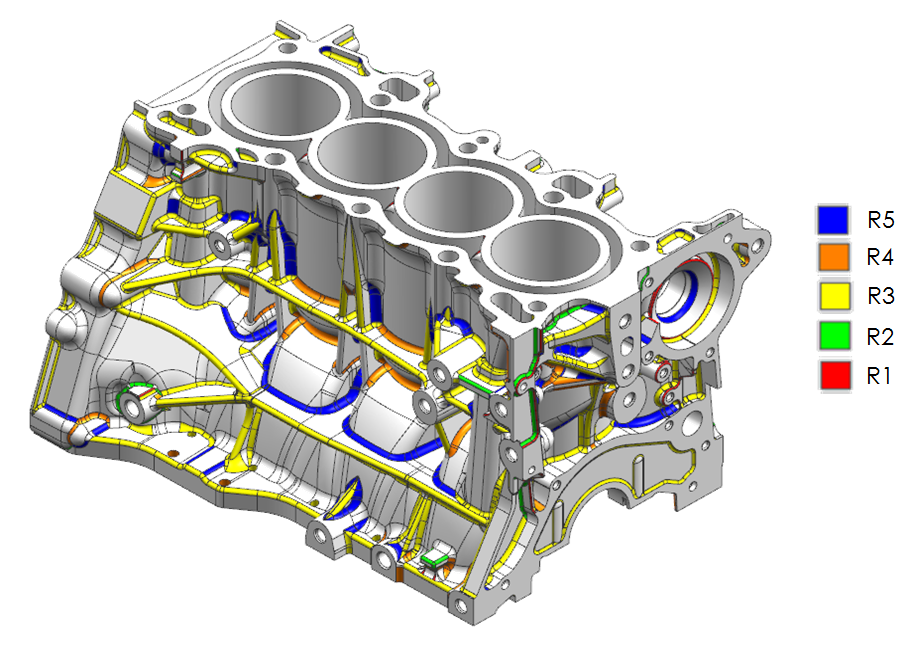

Fillet Checking

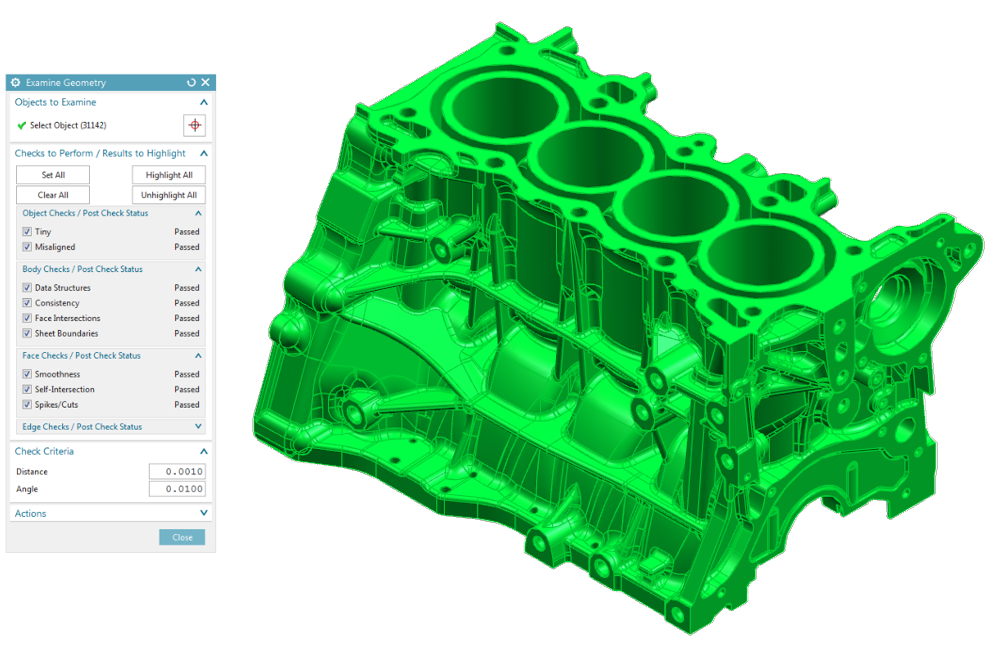

Product Data Quality Checking

Reflection Checking

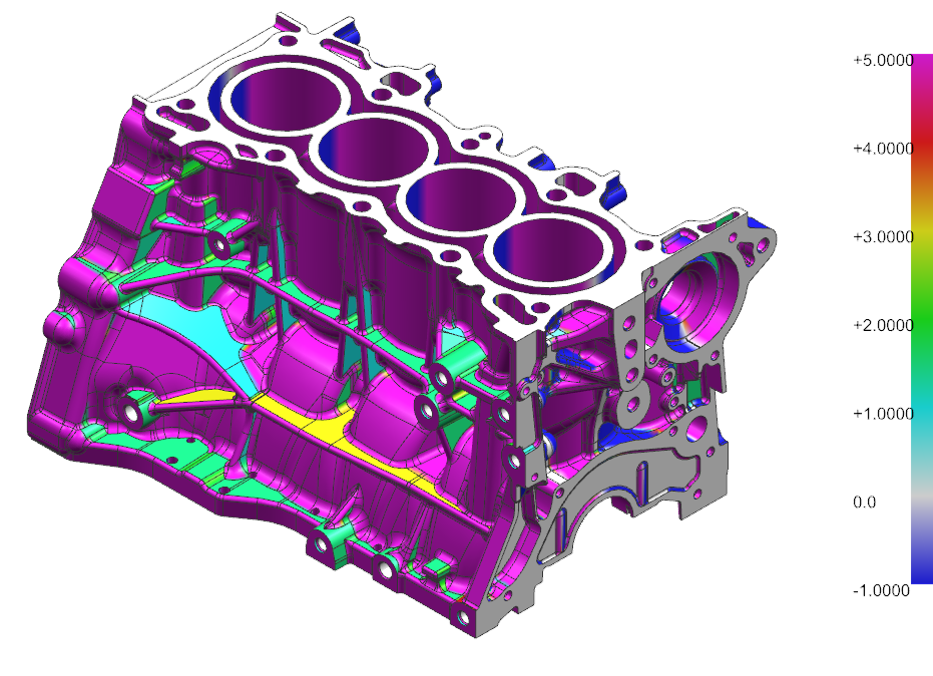

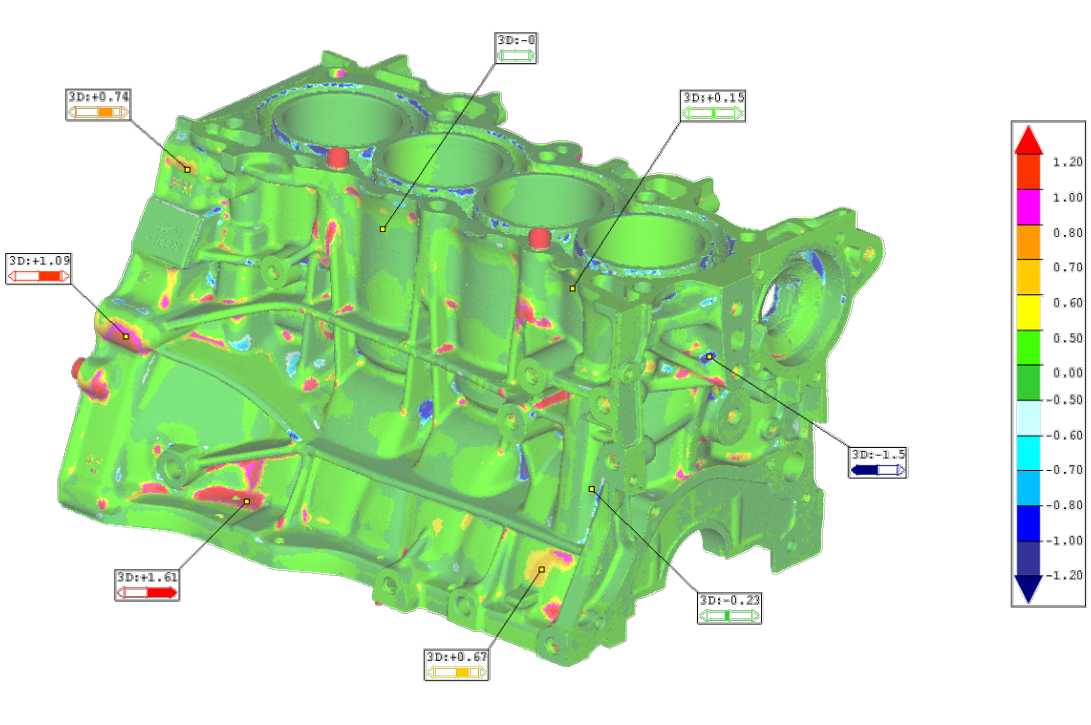

Model Comparison

The combination of 3D scanning and reverse engineering provides an efficient and accurate way to create digital models of physical objects, enabling manufacturers to improve their design and manufacturing processes.

27 June 2023

Viewed 17090 times