article

articleCMM vs. Laser Scanning

CMM vs. Laser Scanning

CMM vs. Laser Scanning: The Battle of Precision Measurement – Which Technology Best Fits Your Application?

In today’s modern manufacturing environment, quality is the cornerstone of success. Ensuring that parts meet specified requirements and GD&T (Geometric Dimensioning and Tolerancing) standards is an essential step that cannot be overlooked.

With a wide range of measurement technologies available—especially the two industry giants, Coordinate Measuring Machines (CMM) and 3D Laser Scanning—many manufacturers face the same question:

“Which measurement technology is the right choice for our application?”

This article provides a clear comparison of the strengths, limitations, and ideal use cases of both technologies, helping you make an informed and cost-effective decision with maximum efficiency.

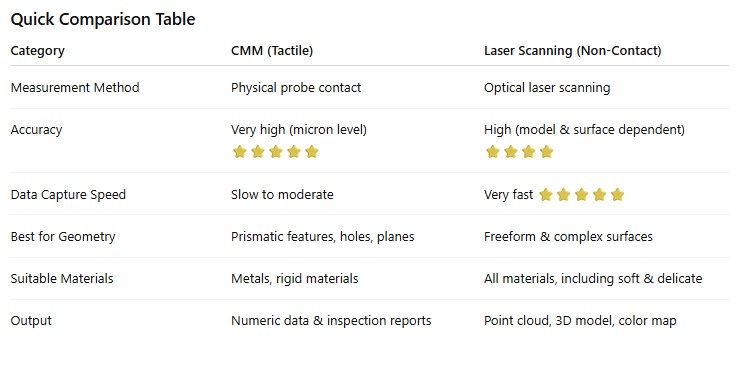

1. Understanding CMM (Tactile CMM): The Gold Standard of Accuracy

A traditional Coordinate Measuring Machine (CMM) uses a tactile probe (typically with a ruby stylus) that physically contacts the surface of a part to collect precise X, Y, and Z coordinate data.

Advantages (Pros)

-

Unmatched Precision:

Delivers micron-level accuracy, making it ideal for applications with extremely tight tolerances. -

GD&T Specialist:

Excellent for measuring geometric characteristics such as circularity, flatness, parallelism, perpendicularity, and true position. -

High Reliability:

Widely accepted as the global standard for OK/NG inspection and final quality decisions.

Limitations (Cons)

-

Slower Measurement Speed:

Since data is collected point-by-point, inspection can be time-consuming for complex parts. -

Physical Contact Required:

Not suitable for soft, flexible, or easily damaged surfaces.

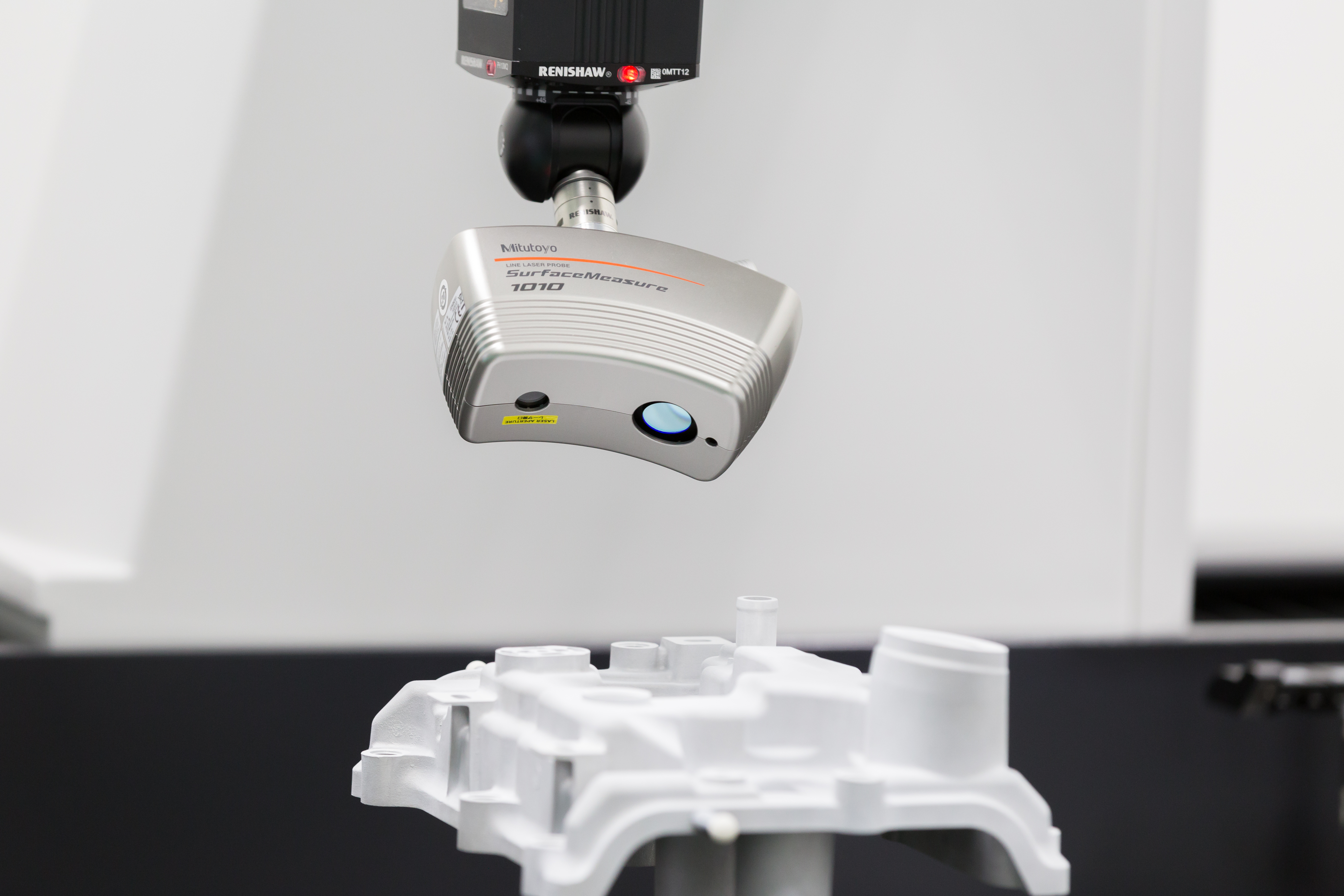

2. Understanding Laser Scanning (Non-Contact): The Master of Speed and Complex Surfaces

3D Laser Scanning works by projecting laser light onto a part and capturing the reflected signal to generate millions of data points (a point cloud), which are then used to create a highly detailed 3D model.

Advantages (Pros)

-

Extremely Fast Data Capture:

Collects full surface data in seconds. -

Non-Contact Measurement:

Ideal for soft materials such as rubber, foam, or delicate components. -

Excellent for Freeform Surfaces:

Perfect for complex geometries such as automotive body panels, turbine blades, and molds. -

Powerful Visualization:

Provides instant deviation analysis using color maps, allowing users to quickly identify out-of-tolerance areas.

Limitations (Cons)

-

Lower Local Accuracy Compared to CMM:

For small holes, sharp edges, or critical features, tactile CMMs typically provide higher precision. -

Challenging Surface Conditions:

Highly reflective or transparent surfaces may require surface treatment (spray coating) prior to scanning.

How to Choose the Right Technology

There is no single “best” solution—the right choice depends on your application requirements.

Choose CMM when:

-

Ultra-high accuracy is required with tight micron-level tolerances

-

GD&T inspection is the primary objective

-

Parts are rigid with relatively simple geometries

-

Certified inspection reports are required for final approval

Choose Laser Scanning when:

-

High inspection speed is critical

-

Parts have complex or freeform surfaces

-

Components are soft or fragile

-

Reverse engineering is required to create CAD models

-

Assembly or mold issues need visual deviation analysis

Both CMM and Laser Scanning are powerful measurement technologies, each with its own strengths. Leading manufacturers often adopt a hybrid approach, using laser scanning for rapid full-surface inspection and CMMs for critical features requiring maximum accuracy.

By combining both systems, companies can achieve speed, precision, and confidence in quality—the ultimate competitive advantage in modern manufacturing.

20 January 2026

Viewed 56 time